- Product Configuration

- Technical Parameter

Production capacity: 30 frames/hour (special optical products)

Feature :

This machine adopts XYZ three-axis precision screw sliding table design, compact structure, high precision, small footprint, CNC software control, suitable for special surface product surface flow coating, easy to operate, high efficiency, wide use.

Using Range :

For PC optical lenses, gas masks, security ball cover, AR/VR technology equipment, helmet protective masks and other special optical products for single-side strengthening, anti-fog treatment.

Cleaning Procedure :

Feeding → electrostatic dust removal → coating → suction → leveling → Pre-drying → curing → blanking

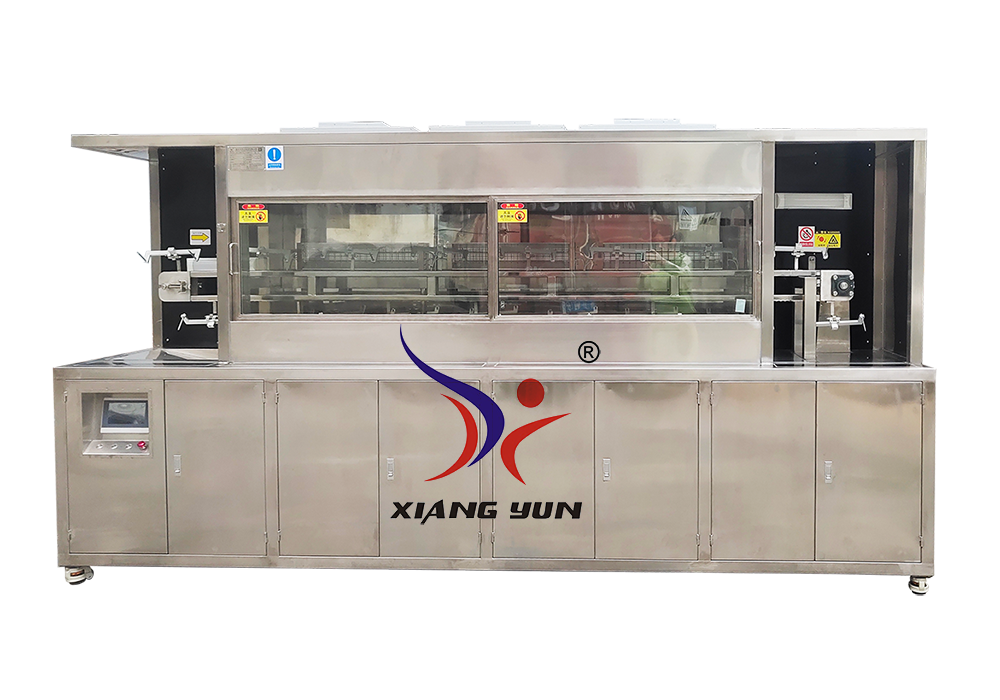

Model | XY-SKLTA0301 numerical control three-axis single-side coating machine | XY-LTYH080 optical product pre-drying line | |

Dimension:L1800×W900×H2050mm | Dimension:L3500×W750×H1850mm | ||

Equipment power | power :1.5KW/220V | power: 7.5KW/380V | |

Production Equipment | Applicator liquid filtration system | 1 set of adjustable gear pump (1 L/min)+ 1 bag filter (0.45um) | |

Drying line air purification system | FFU high efficiency filter 3 groups + 2 groups of air extraction; | ||

Conveying system | Japan Nikki GTR gear motor 1 set (400W/220V) | ||

Suction device | Dive 7A-23D electric aspirator | ||

Control system | A: The coating machine adopts Shanghai Weihong numerical control system, industrial PC+17 inch display, imported servo motor | ||

B: The drying line adopts 7-inch HD touch screen +PLC control, continuous and gap transmission mode, and safety detection device | |||